The 24??media PDFs

The 24??media PDFs

Blog Article

The Only Guide to 24??media

Table of Contents24??media Fundamentals ExplainedThe Facts About 24??media Revealed24??media Things To Know Before You BuyThe 4-Minute Rule for 24??mediaSome Known Details About 24??media

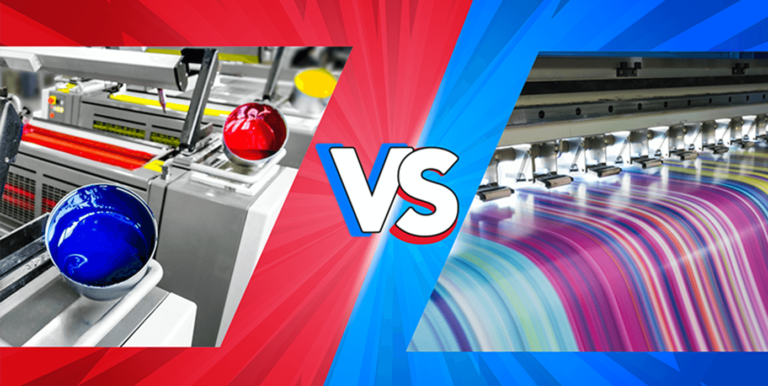

Innovations in print technology are changing the interactions playing area when it pertains to high quality, affordability and innovative capacities. Balanced out printing and electronic printing are the major procedures by which print work are embarked on both utilizing four-color printing approaches. Each choice has its benefits, using various techniques to fulfill the requirements of diverse production projects.

Normally, this has actually been the most constant method for specifically keeping color matches, making it excellent for print runs that only call for fixed printing such as pre-printed kinds, pamphlets, leaflets, calling card, and mass postcard mailings. However, as a result of the fixed nature of litho printing, it is not suitable for variable print pieces that will certainly be sent by mail to individual receivers such as declarations, letters, and personalized postcards.

Indicators on 24??media You Should Know

The most recent improvements in print technology are helping to bring numerous of offset's advantages into the electronic printing world truly altering the face of modern printing! There are some essential distinctions in between Offset Printing and Digital Printing (Large Format Printing). This guide shows the benefits and downsides of each printing technique. There is an undeniable and growing number of benefits to utilizing the electronic print process.

Today's electronic print devices is amongst one of the most cutting-edge on the market. Right here are some of the biggest benefits of using electronic printing: dominate the digital print room, with full-color printing completed in one process and effortlessly published directly from a print documents. Without a lengthy set-up procedure, the calibration time of a certain job is shortened, contributing to quicker print time and total delivery.

The inkjet printing procedure has actually aided to revolutionize the market as well as the quality and rate of the output. The newest inkjet innovation can publish on standard offset stocks with boring, silk, and glossy surfaces. High-grade digital print paired with software-managed color administration techniques adds optimum worth to print pieces and makes manufacturing processes extra reliable than countered.

5 Simple Techniques For 24??media

(https://fliphtml5.com/homepage/yxjqx/24%CA%B0%CA%B3media/)

Specific quantities of ink and printer toner are utilized to avoid waste. Environmentally friendly and naturally degradable inks and toners are additionally readily available for more sustainable printing. Digital print likewise eliminates the demand to clean plates or blankets with dangerous chemicals at the end of the printing process. As the top quality of digital print solutions enhances, the benefits end up being increasingly evident and useful.

Variable data helps companies reach their specific customers and audience with uniquely-created and individualized content. As innovation improves, the high quality of digital printing has become second-to-none, with greater detail, shade suit capabilities and total accuracy. Without the need to wash plates or utilize excess ink, electronic printing is also less wasteful and normally more ecologically pleasant.

("flexo"), entail multiple make-ready actions to move an initial picture to a substratum.

The Ultimate Guide To 24??media

While digital printing is a feasible option for most short-run print workunique celebrations, prototyping, or other considerationsits contemporary capabilities really display in quick turnarounds. Being able to customize product packaging through variable data printing has opened up new possibilities for you to engage with your clients in even more tailored ways. Digital printing, with fewer relocating pieces, is extra nimble than balanced out hereof.

It's a means to mix your product packaging and marketing strategies. Lowered set-up time conserves money on the front end. And considering that these are not large mass orders, smaller companies can pay for to print without having to fulfill the higher and extra costly print limits of standard printing. Digital printing helps secure your brand against counterfeiting by integrating overt and hidden remedies on your product packaging.

Make sure you collaborate with a printing and product packaging companion who has the ideal accreditations. While eleventh-hour printing and customization are a massive benefit, digital might not always be the very best method for you. Offset printing has the benefit of cost-effectiveness with huge print runs, specifically those with advanced ornamental results and specialty coatings.

The Definitive Guide for 24??media

Lithographic presses make use of 2 print platesa favorable and a negativeto transfer top notch shade graphics onto an ideal substrate. The favorable plate, with its smooth surface, attracts oil-based inks and repels water. In comparison, the adverse plate, with its rough texture, takes in water and pushes back oil. Rubber rollers are after that made use of to move the image from the plate to the corrugated surface.

Corrugated paper can in some cases show to be a difficult surface area to print on, however Litho prints to a different surface and is then laminated flooring to it, making it easy to print high-grade photos. It can be extremely consistent, even for futures. In truth, the a lot more you print, the less expensive the expenses end up being for Litho.

What Litho does not provide you is exactly what Digital does, customization. Pricey set up Longer turn-around No Variable Data Printing Smaller shade range, colors can be much less intense Digital printing is the procedure of printing electronic pictures directly onto the corrugated substrate using a single-pass, direct-to-corrugate Resources technique.

Report this page